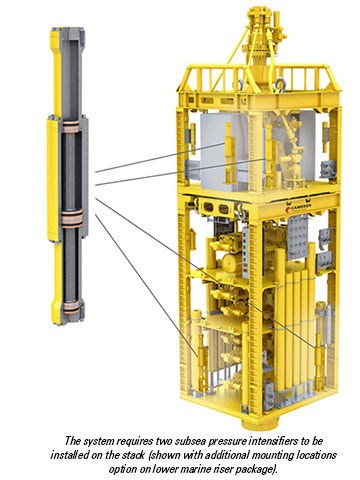

Subsea Pressure Intensifier Schlumberger Cameron Vietnam

Hãng sản xuất: Cameron

Subsea Pressure Intensifier Schlumberger Cameron Vietnam, Subsea Pressure Intensifier Schlumberger Cameron, Subsea Pressure Intensifier

Maximize the working pressure of subsea mounted accumulators

The ability to drill in deeper waters is an ever-increasing advantage in today’s market. One of the most important variables to determining drilling depth capabilities is the amount of usable fluid subsea for activating controls from surface.

The Cameron subsea pressure intensifier (SPI) enables increasing the useable control fluid stored in subsea mounted accumulators by boosting the working pressure from a conventional 5,000 psi [34.5-MPa] up to the full rated pressure of 7,500 psi [51.7 MPa]. Available for new-build rigs or as a retrofittable option, the SPI is a space-saving, economical solution that enables you to

- improve shearing capability

- extend your operating work area into greater water depths

Mr. Trí

Mr. Trí