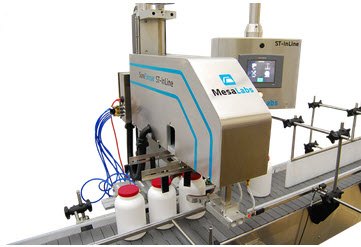

The fully automatic ST-INLINE Bottle Cap Torque Tester samples and tests caps right on the production line. Rugged design, fast response time, ethernet communication make it ideally suited for bottle cap torque testing on any bottling line.

Benefits

- Highly accurate

- Eliminates manual variances

- Fast and easy changeovers

- Decreases risk of ergonomic injury

- Test and record data in U.S. (lb-in) or S.I

Features

- Real time, automatic display

- NIST traceable calibration procedure

- Strain gauge transducer technology

- Automatic container clamping and closure gripping

- Adjustable torque application speed

- Infinite chuck rotation (SERVO)

- Encoder to measure angular degree of rotation (SERVO)

- Lead screw system for height adjustment

- Heavy duty components

Testing Capabilities

- Applied Torque: The ST-INLINE can be used as a benchtop capper, tightening the cap to a customer defined setpoint.

- Release Torque: The ST-INLINE is designed to accurately measure the release (thread break) torque of a cap.

- Peak/Transient Torque: The standard ST-INLINE can measure and display the Applied or Release Peak in a torque testing cycle, however with optional hardware upgrades it is also possible to measure certain torque transients such as the engagement torque of a CR closure system or the peak of the bridge break torque of a Tamper Evident Band.

- Container/Closure Fatigue: By allowing the ST-INLINE to apply and release the cap a number of times, it is possible to evaluate the effect of fatigue on the torque retention and seal quality of the closure and seal.

- Release and Re-apply Torque: When packaging expensive products it is often required to return the tested container to the packaging line. By automatically re-applying the torque to the operator defined setpoint it is possible to save the product.

Specifications

- Capacity: 0-88 lb-in (0-10Nm), both CW and CCW

- Accuracy: 0.5%FS

- Repeatability: +/-0.2 lb-in for one set up

- Calibration: Dead weight, NIST certifiable NIST

- Resolution: 0.001 unit

- Maximum overload: 150%

- Rotation: Infinite

- Torque tests: tightening, removal (CR, CT, etc.)

- Torque units: dNm, Nm, kg-cm, kg-m, oz-in, lb-in

- Torque transducer: strain gauge (350 ohm)

- Control: Unitronics Vision 570 OPLC

- Analog signal acquisition: 12bit, 1ms

- Average response time: 2ms

- HMI display: 320×240 graphical touchscreen

- Communication protocol: RS-232 or RS-485 (optionally USB, Ethernet)

- Real-time clock: 7 year typical battery backup

- Air: 60-80 PSI, 4cfm

- Power: 120VAC, 1A

- Temperature: 41-104°F (5-40°C)

- Relative humidity: 20-80%

- Dimensions: 12″x 16″x 31″

- Weight: ~60 lbs.

- Enclosure: NEMA12

- Material, coating: SS, Clear anodized aluminum

Mr. Trí

Mr. Trí