Rectifier Transformers_Máy biến áp chỉnh lưu Friem

Xuất sứ: Italy

Nhà cung cấp: Pites

Hãng sản xuất: Friem Spa

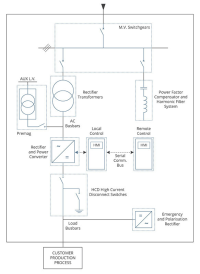

FRIEM designs the complete Rectifier System granting reliability, availability and performance. The Rectifier Transformer is fully integrated in the System through a detailed Technical Specification and optimising the connection to the Rectifier.

• Specialised, experienced and well-proven manufacturers

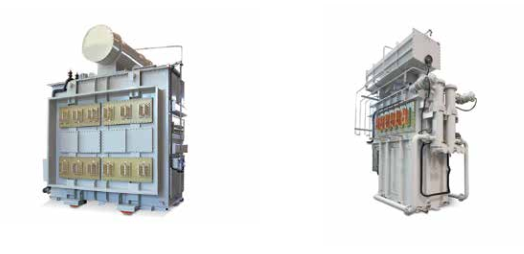

• Type: liquid-filled or dry-type cast-resin

• Capacity: up to 200 MVA

• Primary Voltage: up to 220 kV

• Connections: full-wave (bridge) and half-wave (double star) with IPT

• Tap changer: No-Load (NLTC) or On-Load (OLTC)

• Multi-pulse topologies available: 6, 12, 18, 24 and more pulses

• Cooling system: ON-OF/AN-AF-WF

• Regulating autotransformer available in the same tank to allow on-load coarse voltage regulation.

• Saturable reactors available in the same tank to allow on-load fine voltage regulation.

• Design, manufacture and tests according to IEC and IEEE/ANSI standards.

Designed to meet all types of environmental conditions

• Extreme temperatures from -50°C to +55°C

• Altitude over 4000 m asl

• Corrosive atmospheres

• Seismic zones

• Hazardous areas

All cooling system types available, by means of mineral oil or less-flammable fluids, air or water external cooling mediums, natural or forced circulation.

Protection Features

• O/C, O/V, U/V, Phase Sequence Protection

• Full Temperature Monitoring and Thermal Protection

• Cooling Circuit Monitoring (Pressure, Flow, Leakage, Conductivity)

• On-line oil gas analysis (option)

Special design for Rectifier Application

• Stray losses reduction: transposed cable

• On-Load Tap-changer: MR

• Stainless steel wall for high current bars

• Connections to Rectifier optimised: reduced bars and losses

• Interphase Transformer oil cooled

• Saturable Reactors oil cooled

Support

Support