Key Industries Served: Agriculture, Chemicals, Foods, Minerals, Petrochemicals, Plastics, Textiles

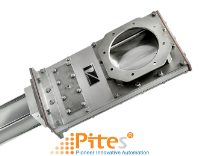

- Gravity flow

- Handles nonabrasive to abrasive powders, granular or pellets

- Design allows for total material flow control

- Wear compensating hard polymer seals

- Seals protected from material flow stream

- Food friendly options available

- Positive seal of dust and fine powders

- Serviceable while in-line

- Material construction options available

- Standard sizes: 5″ – 24″ | 125mm – 600mm

| SPECIFICATIONS | |||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|||||||||||||||||||||||

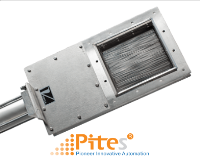

| Size/Bore Options | 6” to 18” Diameter Square or Rectangular with Round Transitions | ||||||||||||||||||||||

| Media | Powder, Pellets, Granulars | ||||||||||||||||||||||

| Connection Options | SVC Standard Stud Pattern, ANSI, DIN, JIS, Custom Flanges | ||||||||||||||||||||||

| Media Temperature | Up to 180°F (82°C) continuous to 250°F (121°C) intermittent service, modifications allow up to 250°F (121°C) continuous or 300°F (148°C) intermittent service | ||||||||||||||||||||||

| Media Pressure/Vacuum | 0 barg, Gravity Flow Only | ||||||||||||||||||||||

| Valve Construction Options | 304 or 316L Stainless Steel, and Carbon Steel | ||||||||||||||||||||||

| Material Contact Options | 304 or 316L Stainless Steel, and Carbon Steel | ||||||||||||||||||||||

| Seal/Seat Material | Nylon, PET, UHMW, Glass Filled Teflon, Natural Rubber, Kryptane, and/or Silicone Rubber | ||||||||||||||||||||||

| Drive/Actuation | Double Acting Air Cylinder with Solenoid Operated Air Control Valve, Electric Actuator, or Hand Wheel | ||||||||||||||||||||||

| Position Confirmation | Magnetic Reed, Proximity, or Mechanical Limit Switches | ||||||||||||||||||||||

| Compliance Approvals | CE, ATEX, FDA | ||||||||||||||||||||||

| Industry Use | Agriculture, Chemicals, Foods, Minerals, Petrochemicals, Plastics, Textiles | ||||||||||||||||||||||

Mr. Nghia

Mr. Nghia nghia.pitesco

nghia.pitesco