Electro sensors, Shaft speed Electro sensors, cảm biến tốc độ trục Electro sensors, Electro sensors việt nam

Nhà cung cấp: Pisteco Việt Nam

Hãng sản xuất: Electro Sensors

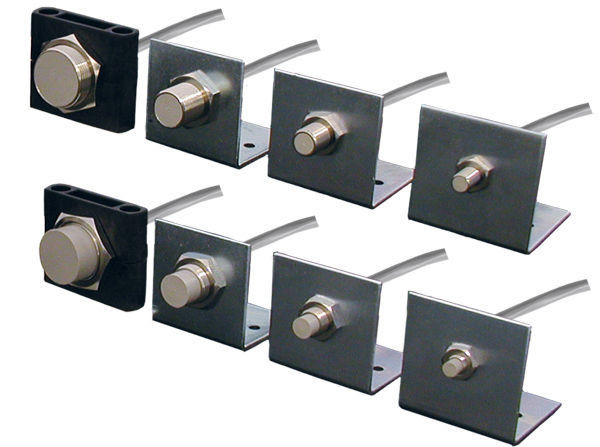

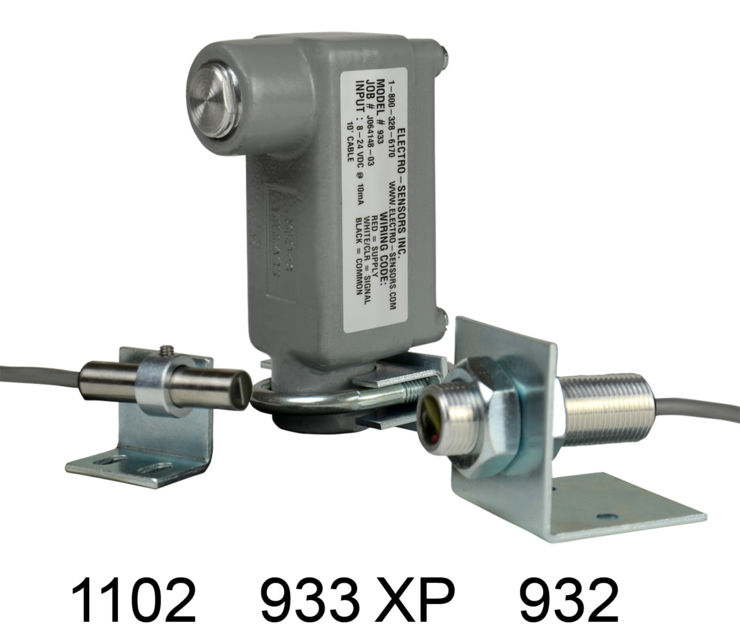

1102 / 932 / 933 XP

Shaft Speed Sensors - Magnetoresistive

Features:

- NPN open collector output

- Non-contact, large gap distance sensing

- Maximum switching frequency of 20 KHz

- Compatible with PLC digital I/O's

- 5-24 VDC operation

Magnetoresistive sensors are used with magnetic targets such as Pulser Wraps, Pulser Discs, or 60 Pole Pair Magnet Wheels to provide digital pulse output signals. These sensors are also used in applications where only one magnet is present for counting, function start/stop, or orientation alignment of mechanical or electronic indexing equipment.

1102 (Stainless Steel)

The 1102 is 7/16 inch in diameter, non-threaded stainless steel, and is 2 inches in length. It is supplied with a mounting bracket and 10 feet of 3-conductor shielded cable.

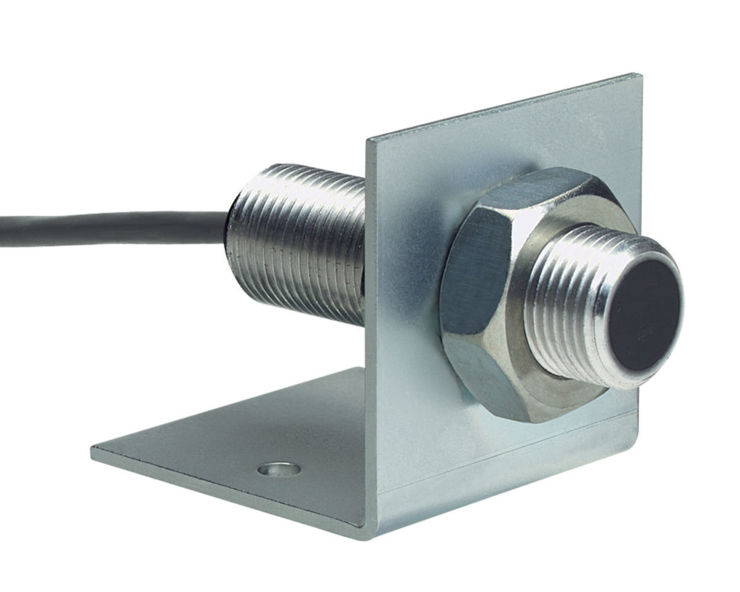

932 (Aluminum)

The 932 is 3/4 inch in diameter, with 3/4-16 UNF threads, and is 2-1/2 inches in length. It is supplied complete with a mounting bracket, jam nuts, and 10 feet of 3-conductor shielded cable. It can also be supplied with a conduit adapter allowing it to fit a 3/4 inch conduit fitting.

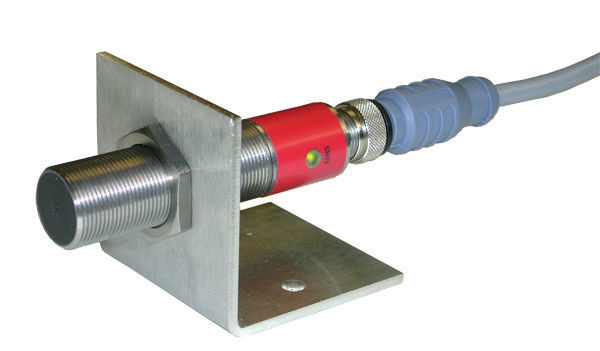

600 SERIES PROXIMITY

Proximity Sensors

Features

- Non-contact sensing

- Solid-state - no moving parts

- Durable corrosion resistant metal housings

- High speed repeatability

- Short-circuit and reverse polarity protection

- Outputs CMOS compatible

- Full output signal down to zero Hz

- LED operation indicator on all models

600 Series Proximity Sensors are active digital sensing devices that generate one pulse per pass of an actuating target within their sensing field. No direct contact with target material is necessary. Each sensor is entirely solid state with no moving parts to wear out. The wide range of supply voltages to the 600 Series permits direct interface with low voltage, solid state controls such as programmable controllers and electromechanical relay loads. All sensors are polyurethane or epoxy encapsulated and are provided with a mounting bracket, jam nuts, and 6 feet of cable.

HE950

Gear Tooth Sensor

Features

• Senses broad range of ferrous target sizes

• Senses a frequency range up to 12 kHz

• Gap sensing capability up to 3 mm

• Full output down to zero Hz

• Rugged, NEMA 4 sensor housing

• Available with 3/4in or 18mm threads

The HE950 produces digital pulse signals for use with speed switches, tachometers, counters, signal conditioners, or as a direct pulse input into programmable controllers (PLCs). It incorporates a dual Hall Effect sensor and signal processing that switches in response to differential magnetic signals created by a ferrous target. Typical targets are gear teeth, keyways, or bolt heads, and the circuitry achieves true zero-speed operation down to zero Hz. Each sensor is entirely solid state with no moving parts to wear out, providing a low maintenance rugged and long-lasting sensor.

916A / 917A (REPLACEMENT ONLY)

Analog Shaft Speed Sensors

Features

- Large gap non-contact sensing

- Signal transmission up to 1,500 feet

- Easy to install - no maintenance

- Rugged and reliable

916A Sensors have a 3/4" threaded aluminum body, are supplied with a mounting bracket and jam nuts, and are recommended for use with Pulser Discs and Split Collar Pulser Wraps.

917A Sensors are mounted in a rugged cast aluminum enclosure. 917A sensors are also supplied with a mounting bracket and are recommended for use with Pulser Discs and Split Collar Pulser Wraps.

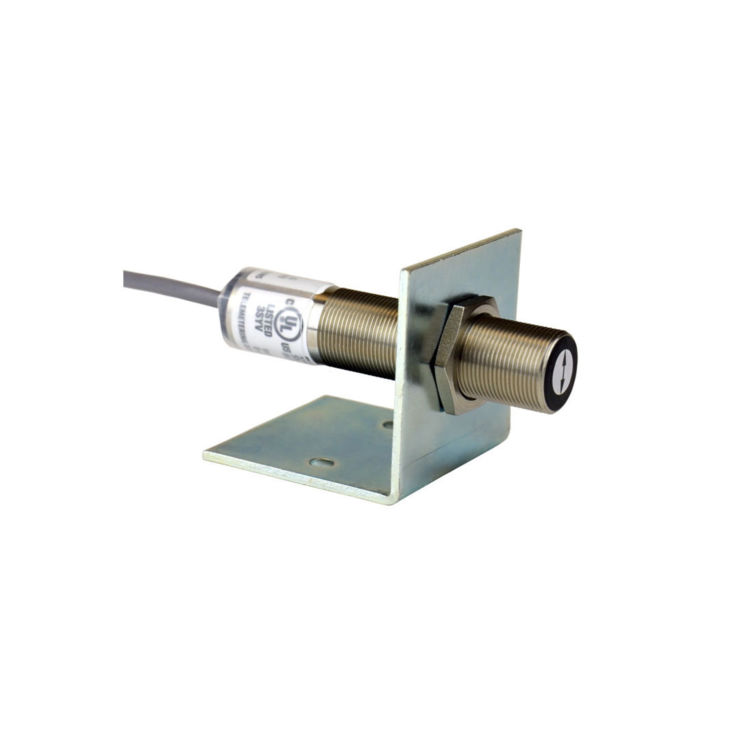

931 XP HALL EFFECT

Explosion Proof Hall Effect Sensor

- Square-wave pulse frequency output, NPN open-collector

- Zero speed operation with no signal loss

- 5-24 VDC powered

- 1/2" NPT conduit port

- Non-contact, large gap distance sensing

- Works with magnetic Electro-Sensors pulser discs / wraps

- 931 XP – UL Listed Class I, Div I (C, D) Class II, Div I (E, F, G) Class III

The 931 XP is mounted in a cast aluminum enclosure and is supplied with a mounting bracket and 10 feet of 3-conductor shielded cable. The conduit opening is 1/2 inch NPT.

- Class I, Div I (C, D) Class II, Div I (E, F, G) Class III

- XLB-1 enclosure

931 XP Hall Effect speed sensors use magnet-sensing Hall Effect IC's to produce a digital pulse signal to interface with speed switches, tachometers, counters, signal conditioners, or PLC's. Hall Effect sensors provide true zero speed operation with square-wave output and immunity to electrical noise.

A pulser disc or split collar pulser wrap with embedded magnets is mounted on the monitored shaft. As the shaft rotates, the magnets pass in front of the sensor causing the sensor to switch high and low, thus producing a digital pulse output. The sensors provide a digital square wave signal with a 50/50 duty cycle when used with pulse generators that have evenly spaced magnets of alternating polarity, such as Electro-Sensors Model 255 Pulser Disc.

ST420

4-20 mA Shaft Speed Sensors

Features

• 2-wire, loop-powered 4-20 mA analog output

• No user calibration: works right out of the box

• Works with shaft-mounted pulser targets (disc/wrap)

• Rugged stainless steel M18x1 housing

• Reverse-wiring protected

• UL listed, Intrinsically Safe (IS)

• Class I, Div I (C, D) Class II, Div I (E, F, G) when

used with an IS barrier.

The patented ST420 detects passing magnets of a shaft-mounted pulser disc or wrap and outputs a smooth, continuous 4-20 mA analog signal in direct proportion to shaft rotation speed.

SPEEDTALKER-DN(BH) DEVICENET

Shaft Speed Sensor with Alarms and DeviceNet Network Interface

Features

• Real time shaft speed and up to four programmable

over/under speed alarms

• Easily integrates into any DeviceNet network

• DeviceNet group 2 slave with Poll, COS and Explicit Message connections

• Network powered from the network cable - no additional power source needed

• ODVA conformance tested

• Rugged NEMA 4X, IP67, stainless steel M18x1 housing with M12 DeviceNet

micro connector

• Mounting bracket and two stainless steel jam nuts are included

SPEEDTALKER-DN(XP) DEVICENET

Shaft Speed Sensor with Alarms and DeviceNet Network Interface

Features

• Real time shaft speed and up to four programmable

over/under speed alarms

• Integrates into any DeviceNet network

• DeviceNet group 2 slave with Poll, COS and Explicit

Message connections

• Network powered from the network cable -

no additional power source needed

• ODVA conformance tested

• Rugged cast aluminum explosion-proof housing with internal DeviceNet

open-style connector

• UL listed, (XP) Class I, Div I (C, D) and Class II, Div I (E, F, G), NEMA 4X

SpeedTalker-DN(XP) detects passing magnets of a shaft-mounted pulser disc or wrap, calculating shaft speed and alarm functions for access over DeviceNet.

Mr. Hà

Mr. Hà live:ha_1652

live:ha_1652