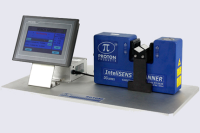

DG Series Diameter Gauge_Proton Vietnam, Thiết bị đo đường kính cáp, Proton PTC Vietnam

Xuất sứ: UK

Hãng sản xuất: Proton

Introduction

Operating Principle

Specifications

|

Model: DG2006/ DG1030/ DG2030/ DG1060/ DG2060/ DG1130/ DG2130

|

|

|

|

|

|

|

|

|---|

| Mr. Hà |

|

ha@pitesco.com ha@pitesco.com

|

|

0914 643 179 0914 643 179

|

|

| Ms Nguyệt |

|

services@pitesvietnam.com services@pitesvietnam.com

|

|

0918 805 949 0918 805 949

|

|

|

Đang online | 55 |

|

Lượt truy cập | 34189330 |

DG Series Diameter Gauge_Proton Vietnam, Thiết bị đo đường kính cáp, Proton PTC Vietnam

Xuất sứ: UK

Hãng sản xuất: Proton

|

Model: DG2006/ DG1030/ DG2030/ DG1060/ DG2060/ DG1130/ DG2130

|

|

|

|

|

|

|

|

|---|

CÔNG TY TNHH KỸ THUẬT CÔNG NGHỆ VÀ DỊCH VỤ TIÊN PHONG

Add: Số nhà 21, đường số 12, khu nhà ở Vạn Phúc 1, Tổ 10, khu phố 5, Phường Hiệp Bình Phước, Thành phố Thủ Đức, Thành phố Hồ Chí Minh, Việt Nam.

Tel: +84-8.3517 6474 /75 - Fax: +84-8.3517 6476 - HotLine: 0914643179

Email: ha@pitesco.com

Ms. Trinh

Ms. Trinh trinh trinh

trinh trinh